Battery failures originate at the scale of individual particles but with some analytical tools, the true causes of these failures are hard to determine, either averaged out, or completely inaccessible. This is a problem charge photometry can solve. Our new technology captures real-time, single particle data so you can watch structure, and performance evolve, particle by particle, as your battery works. This makes it possible to pinpoint exactly where and why failure starts, and to connect that to measurable material properties.

The problem with ensemble averaging

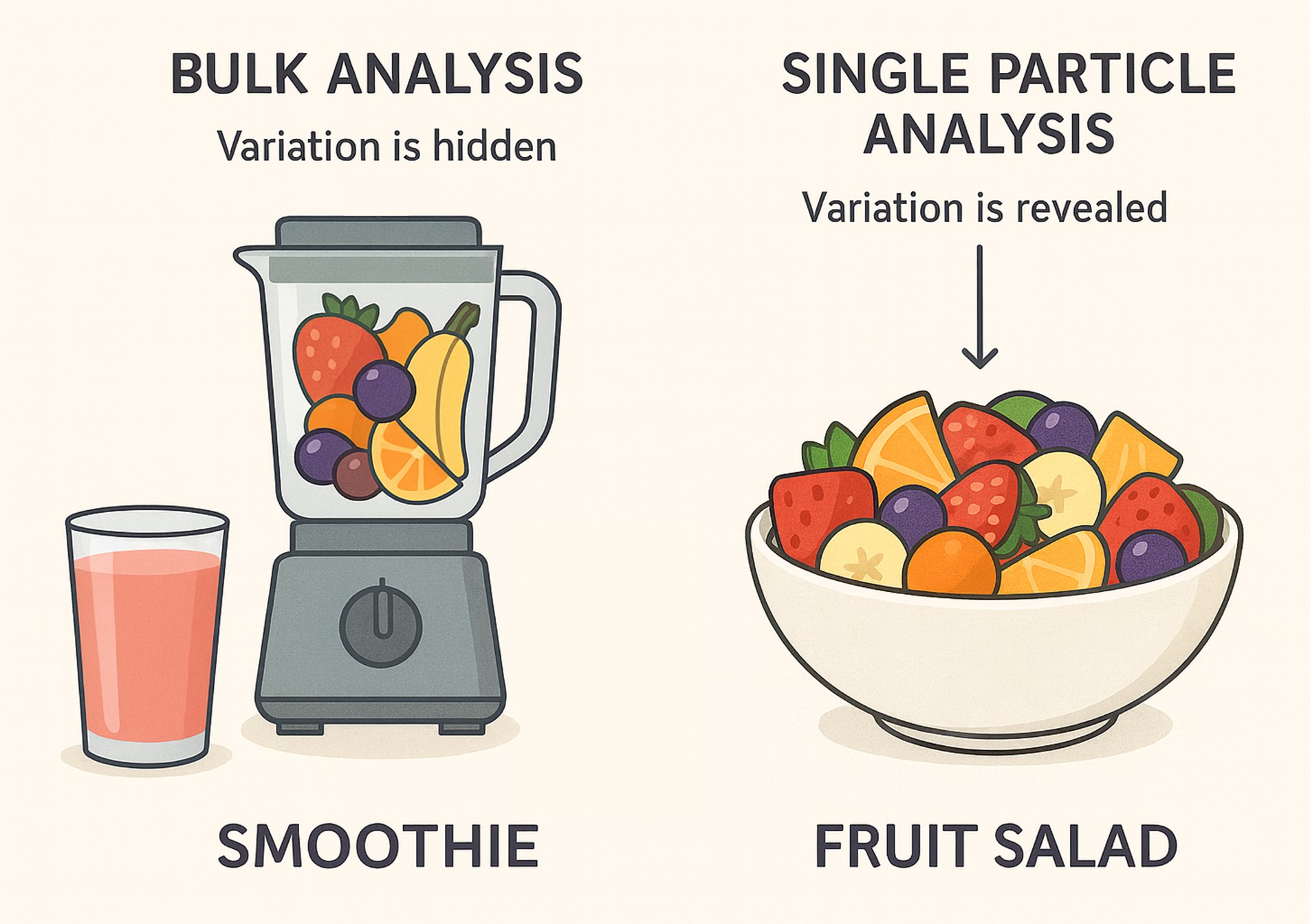

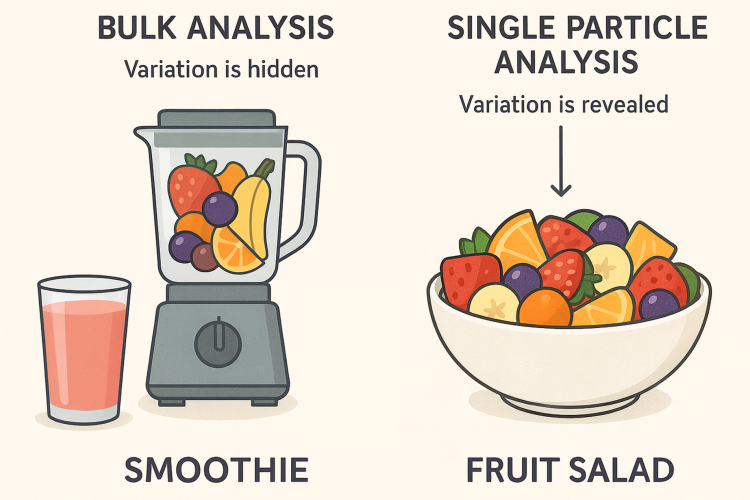

Established techniques like XRD, electrochemical testing, and impedance spectroscopy give you valuable information. But they share a critical flaw: they average results across large numbers of particles. This is like trying to study a fruit salad after blending it into a smoothie. You can still measure nutrition overall, but the details (e.g., which fruits were “crisp”, which were bruised, which tasted sweetest) are gone.

In battery terms, averaging hides the reality that:

- Some particles charge or discharge faster or slower due to size, structure, or local environment

- Certain particles degrade first and contribute to cell failure

- Phase transformations and reaction rates vary widely across a single electrode

Without single particle resolution, these hidden variations remain invisible and so does the path to better performance.

Why it matters for research and industry

For fundamental science

Single particle analysis turns theoretical assumptions into directly observed events:

- Phase transformations that look “smooth” in ensemble data can happen in abrupt, particle-specific steps

- Particle-to-particle variations in reaction rate can reveal different kinetic limits for fast charging

- By watching ion gradients form inside single active particles, researchers can see the early signs of degradation and uncover the kinetic bottlenecks that reduce battery capacity

- Local defects can be linked directly to early failure

This means researchers can build more accurate particle-level models and validate them against reality, not just averages.

For applied development

In commercial development, the stakes are higher:

- Promising chemistries can sometimes fail during scale-up

- Fast-charging protocols cause unpredictable degradation patterns

- “Identical” batches of electrode materials vary in lifetime and capacity

Single particle analysis shows why this happens, helping teams:

- Identify failure modes early in testing

- Link material design choices to long-term performance

- Reduce trial-and-error in development cycles

From post-mortem to live observation

Post-mortem analysis is like arriving at a crime scene after the suspect has fled: you see the damage, but not the chain of events that caused it. Additionally, with post-mortem analysis you are never quite sure if the damage you see was actually done when you disassembled the cell. Charge photometry changes this. It lets you watch, in real time, how particles behave, transform and degrade:

- See exactly which particles crack first and why

- Track phase transformations as they happen

- Spot performance outliers before they become hotspots for degradation

- Measure the spread of reaction rates under fast charging

The future of battery materials insight

As batteries move toward more complex chemistries and higher demands, relying only on ensemble-averaged data will limit progress. Single particle analysis offers a direct, visual, and quantitative link between material structure and battery performance. For researchers, it’s a new lens on fundamental mechanisms. For developers, it’s a faster route to reliable, scalable materials.

Ready to advance your battery materials research? Whether you’re investigating fundamental mechanisms in an academic setting or developing next-generation materials for commercial applications, contact our team to learn how charge photometry and the illumionONE can provide the single particle insights needed to advance your battery materials research.