Anode electrode optimisation example

Monitor degradation – Extend battery lifetime

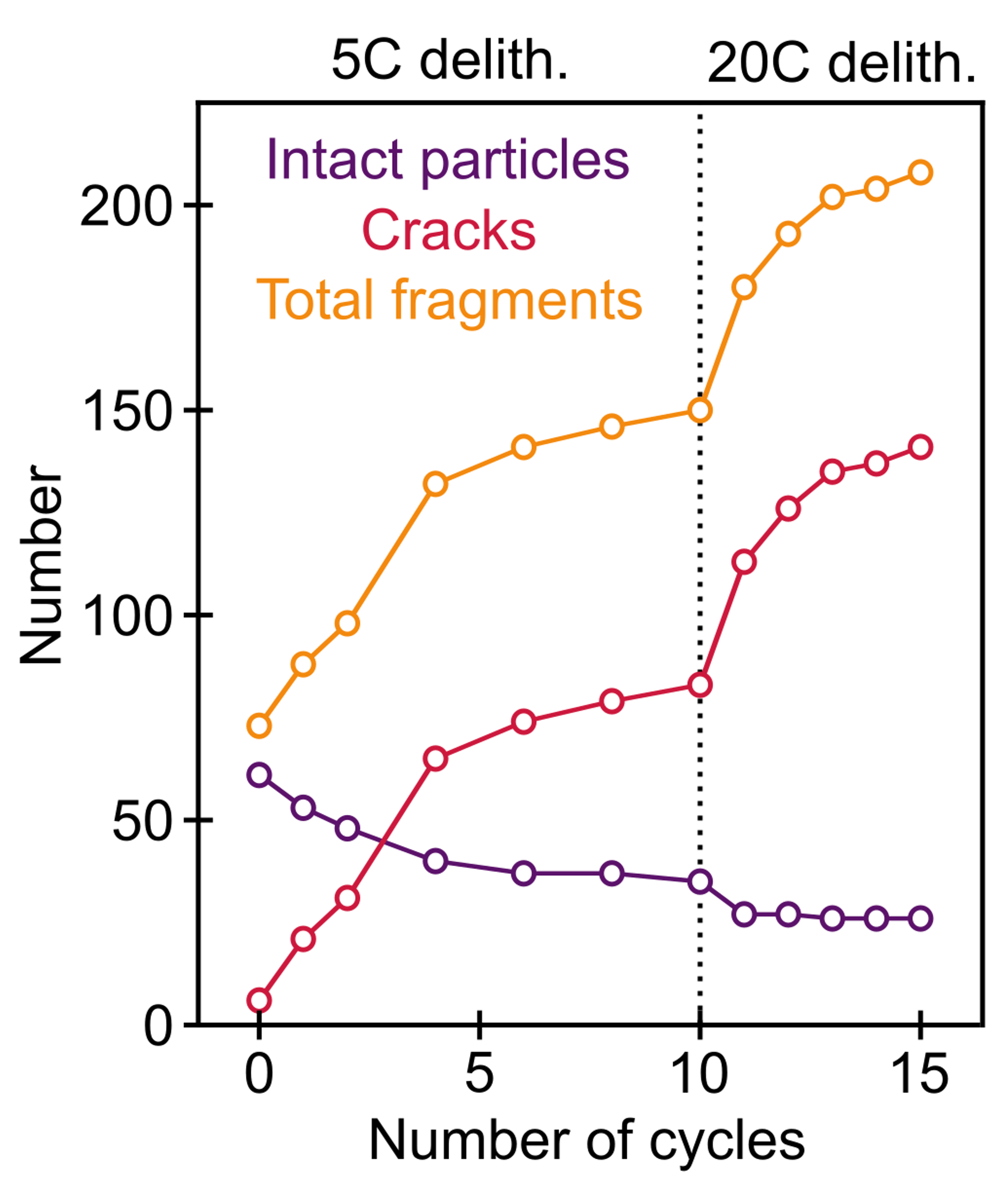

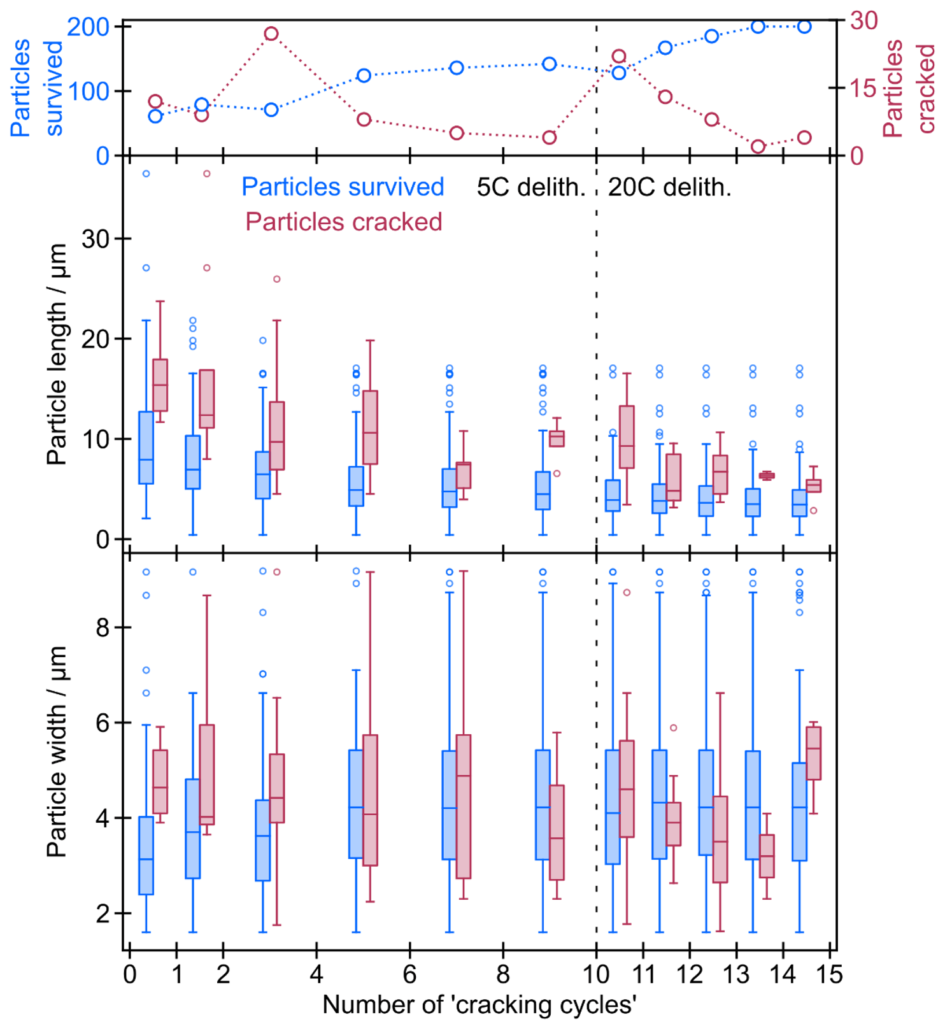

In this example, charge photometry is used to monitor particle degradation in a high-rate anode material across repeated fast charge-discharge cycles. The technique quantifies cracking and fragmentation in real time, helping researchers identify which morphological features impact durability – and how to optimise them for longer battery life.