Battery researchers can develop electrode materials that look great on paper but when they are tested in the lab, they do not always perform as expected. The gap between what should work and what does work can be a frustrating one. It is related to the fundamental challenge of understanding what happens inside such materials during battery operation.

Traditional electrochemical testing tells us the what: capacity loss, voltage drop, impedance growth.

Post-mortem analysis reveals the aftermath: structural changes, particle cracking. The crucial piece of the puzzle relating to the how and the when these changes occur during cycling remains largely invisible.

This is precisely why researchers have been searching for ways to peer inside working batteries in real-time. They need to see degradation as and when it happens, not just survey the aftermath.

This is where charge photometry comes in, a technique that can fill in the information gap.

What is charge photometry?

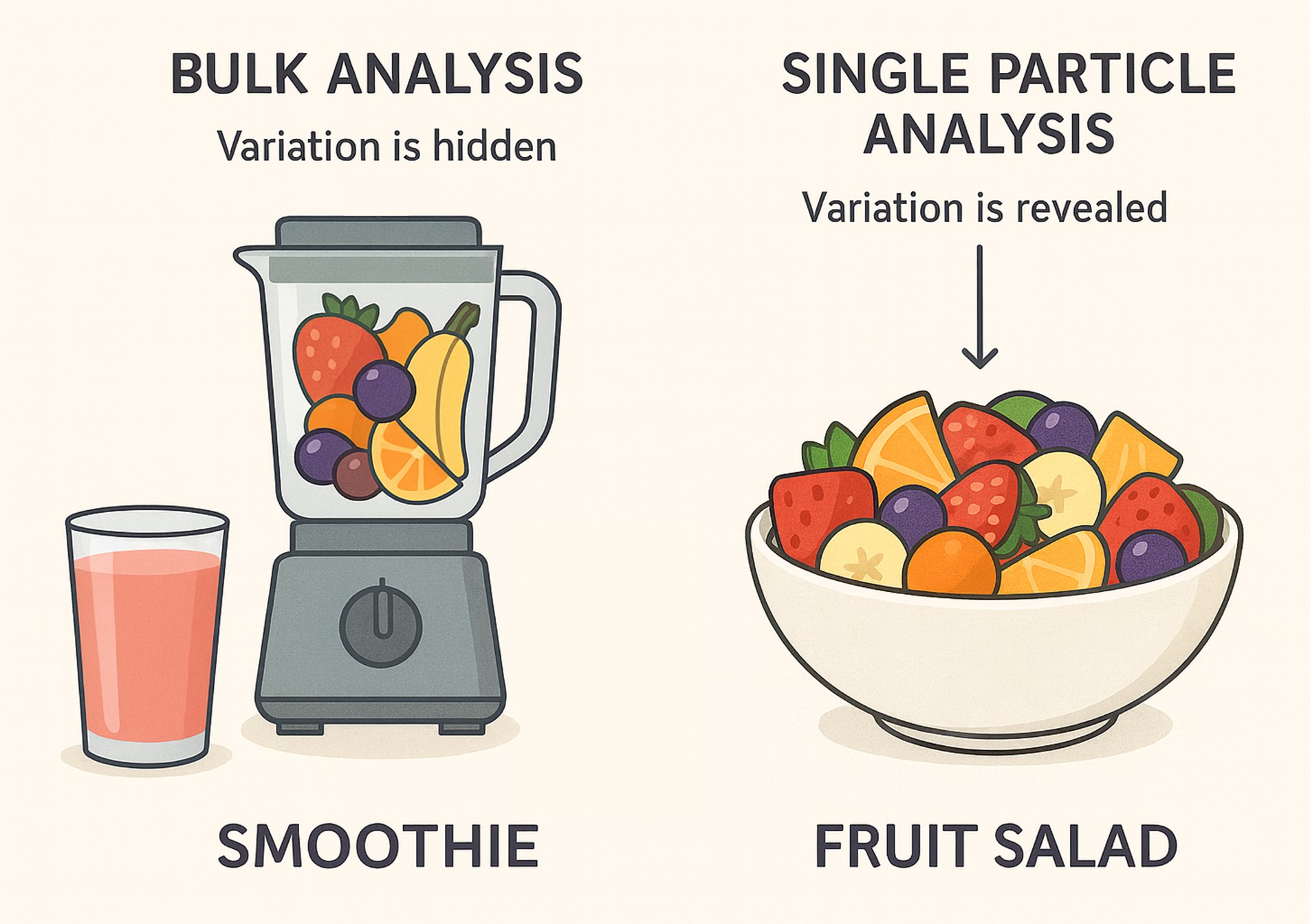

Charge photometry lets you watch individual battery particles charge and discharge in real time inside a working battery. Instead of getting averaged results from thousands of particles mixed together, you can see exactly what each one is doing, while monitoring your cell’s electrochemistry performance.

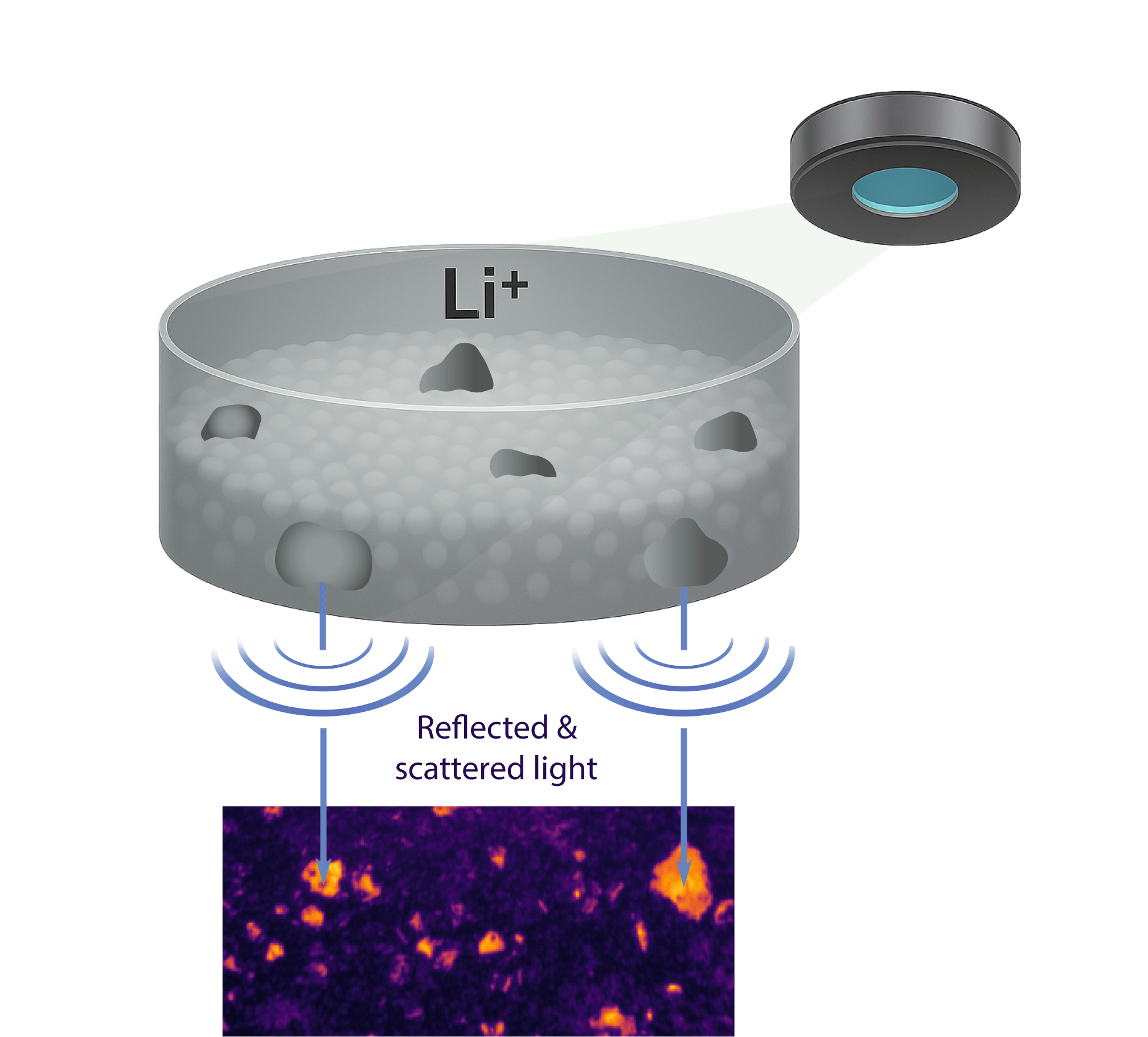

Here’s how it works: When ions move in and out of battery particles during charging, they change how the material interacts with light. By tracking these changes, we can create a live map of which parts of your electrode are working well and which are not.

Think of it like switching from listening to a muddled recording of an orchestra to being able to pick out each individual instrument. Suddenly, you can hear exactly which violin is playing the most brilliant tune.

Why does charge photometry matter?

Most battery problems come down to the fact that not all particles behave the same way. Some charge quickly, others slowly. Some hold their charge well, others fade fast. Readily available, traditional methods give you an average of all this activity, which can mask the real issues.

However, your battery is only as good as its worst-performing particles. If 10% of your particles aren’t pulling their weight, that’s what limits your overall performance. Until now, identifying and fixing these problem particles has been very difficult and challenging.

What you can do with this technology

See problems as they happen: Instead of running a test and wondering what went wrong, you can watch the issues develop in real time. Maybe some particles aren’t getting enough lithium, or certain areas are charging too fast and creating hot spots. You’ll know immediately.

Understand why materials fail: Have you ever had a material that worked great for the first 50 cycles and then started degrading? With charge photometry, you can see exactly which particles start failing first and why.

Test faster: Since you’re getting multiple types of data from each test (i.e., particle behaviour, morphology changes, and standard electrochemical data), you need fewer experiments to get answers.

Design better charging protocols: Watch how different charging speeds affect your materials and find the sweet spot between fast charging and long life.

Real examples of what charge photometry solves

A research team we worked with was examining the effect of particle morphology for their fast-charging anode material. Charge photometry revealed that during fast charging, the outer edges of particles were reaching full charge while the centres lagged significantly behind, ultimately leading to particle cracking.

This insight revealed that particles with a modified particle shape would be beneficial in improving the material stability during fast-charging conditions.

Introducing the illumionONE system

We designed the illumionONE to be the kind of tool you’d actually want to use regularly, not something that sits in a corner gathering dust. It’s about the size of a desktop printer, works with a slightly modified standard coin cell geometry, and fits into whatever testing routine you’re already using.

The idea was to make advanced battery analysis as routine as possible. No specialised training, no major workflow changes, just better data about how your materials really work.

Why does this matter now?

The battery industry is moving faster than ever. Research labs and companies are wanting to develop better materials quickly.

Meanwhile, the materials themselves are getting more complex. Next-generation electrode materials require us to move beyond traditional bulk measurements. You need to see what is happening at the particle level.

Getting started with charge photometry

If you’re working on battery materials and are frustrated by the gap between expected and actual performance, charge photometry might be exactly what you need. It’s not going to solve every problem, but it will show you things about your materials that you’ve never been able to see before.

And once you can see what’s really happening, you can start fixing it.

Interested in learning more? We’re happy to discuss how charge photometry might fit into your research.

Drop us a line or schedule a call to see what insights might be waiting in your materials.